URBAN PEST MANAGEMENT

BEST PRACTICES FOR

GOVERNMENT BUILDING AND STRUCTURES

|

||

Prevention

following the Supreme Court Ruling is

the key to proper, effective, least hazardous, and legal urban pest management

programs in all government buildings and structures.

Briefly,

the SC decision that upheld all lower court rulings, the MMC Pest Control Board, and the Department of Health Circular 155 ruled that it is the National Committee on Urban Pest Control [NCUPC] that has jurisdiction

over urban pest control. As cited by the ruling, “the NCUPC was created pursuant to the Memorandum of Agreement [MOA] signed

by the Office of the President, the Metro Manila Commission, the Department of

Labor & Employment and other Government Agencies and Non-Governmental Organizations

per Presidential Decree 856 [Sanitation Code], 522 [Sanitation requirements for

establishments catering to traveling public], and 1096 [Building Code], PD

1423, and President Corazon Aquino’s Executive Order 432, RA 3850, PD 1423 as

amended by EO 128. Through the NCR Pest Control Board and the MMDA Pest Control

Board, the practice of pest control is governed.” The NCUPC, by virtue of the MOA harmonized the laws

of various government offices related to pest control.

If

the conditions that attract and support pests, that is, the presence of food or

organic debris, water, shelter, and access are improperly eliminated, then

other management practices are most likely to fail. The building management

including all occupants must be involved in the planning, design, construction,

remodeling or retrofitting of the government building and structures should be

aware of the need for long-term prevention or suppression of pest problems. Pest

prevention will reduce overall costs of pest control operations as well as

other maintenance and operating expenses.

A

thoroughly and legally integrated approach to urban pest management in government

buildings and structures begins in the early planning stage. Too often, pest

management or pest proofing is not considered, is neglected, or is just taken

for granted at this point. The way a government building or structure is put up

including materials, construction techniques, and attention to detail will

impact any future pest management efforts throughout the life of government building

or structure. So there’s a need to consider pest management needs during

design, development and construction of government building and structure where

the National Committee on Urban Pest

Control Licensed Pest Control Provider follows the phases of building and

structural construction means to incorporating features that will exclude

pests, minimize pest habitat, and promote proper sanitation.

Several

basic building and structural features can cause most of the pest problems.

Many government buildings and structures have pest exclusion problems at

doorways and windows. Heating, air conditioning, plumbing, electrical service,

and fire sprinklers provide other pest entry points. Even in newly constructed government

buildings and structures, electrical conduit, water and gas lines, and

communication cables generally have large openings that permit pest entry. Wall

cavities, ceiling cavities, and the space beneath floors can all provide pest

shelter. From these areas, pests generally have ready access to the rest of the

building and structure. Utilities, overhead suspended ceilings, and air

conditioning ducts provide a very effective pest distribution system. So

there’s a need for all existing government buildings and structures to be

regularly inspected by the NCUPC to

assess them in terms of pest infestation and the soundness of the structures

against termite and other pest damages. The NCUPC then prepares the technical

program to form the basis for

bidding pest control services per RA

9184 [Government Procurement Reform

Act].

Although

pest-resistant building and structure practices most commonly reduce shelter

and access, they can also reduce food and moisture sources through proper

sanitation, reducing trapped moisture, and improving drainage.

While

proper construction practices are the emphasis here, they cannot stand alone. A

strong and legal urban pest management and maintenance program is essential.

Poor sanitation or leaving entryways open will make even the best designed and

constructed building susceptible to pest problems. Using the practices

discussed below, together with regular

routinary inspection conducted by National

Committee on Urban Pest Control Licensed Pest Control Provider, and

awareness of potential pest problems among staff management of government

building and structure and occupants by the NCUPC information dissemination education, can greatly reduce or

eliminate the potential for infestations, especially when followed by

responsible maintenance.

The

following guidelines and best practices illustrate the variety of practices

that can be used and their value in pest prevention in government structures

and buildings. No single practice will work equally well in all circumstances.

Certain practices listed below may not be appropriate where structural

requirements or budget considerations preclude them. Once the basic principles

are understood, there is no substitute for resourcefulness and ingenuity in

developing practical, site-specific solutions.

1. PRE-CONSTRUCTION

GUIDELINES AND BEST PRACTICES

A. FOUNDATION AND

SLABS

- Eliminate gaps or flaws in

foundations and slabs, or where the wall framing meets the foundation or

slab floor. These openings may be large enough to allow entry for insects

and rodents. Older buildings commonly have cracked foundations, cracked

plaster or mortar, warped siding, or broken and torn vent screens that

allow pest entry.

- Install physical barriers

beneath joints or other discontinuities in the foundation. No hidden cold

joint should exist in the foundation unless there is an installed physical

barrier. A sheet of metal barrier to termites can be installed from below

the wall sill plate or first block course horizontally to embed in a

mortar joint.

- Include the design of footings

for brick, stone, or other veneers with the other pre-construction

foundation planning. A concrete bearing ledge that is poured integrally

with the concrete foundation should support these heavy veneers. If poured

as part of the foundation, the ledge prevents termite entry into the

building between the footing and the foundation.

- Use a sand barrier. Use a

3-inch layer of sand underneath slab construction. Use 1-3 millimeter

particle size in place of unsifted sand to provide a permanent termite

barrier for subterranean termites. This will prevent termites from

penetrating the cracks in the slab construction.

- Use natural durable wood, kiln

or chemical-treated wood or non-wood materials. The only sure prevention

of termite problems is the use of building materials other than wood.

- Eliminate all wood-to-soil

contact as much as possible. Soil should always be from 6 to 18 inches

below any wood member, the greater the distance, the better.

- Extend foundation below ground. Good foundations will normally stop rodents from getting into buildings; however, if foundations do not rest on bedrock, they should extend vertically below ground at least 3 feet or have an L-shaped curtain wall about 2 feet deep with a 1-foot projection from the building. On piled foundations, the reinforced concrete beam spanning the piles should extend 3 feet below ground to stop rodents.

- Modify foundations on older

buildings with concrete or metal barriers to stop rodents from digging

their way in.

- Check foundation vents to make

sure they are tight and appropriately screened (use a hardware cloth to

exclude rodents).

- Avoid burying or storing

cellulose-containing material (such as wood scraps, form boards,

vegetation, stumps, large dead roots, cardboard, trash, and foreign

material) near or under the structure. To reduce chances of termite

infestation, no cellulose-containing material should be buried on the

building lot within fifteen feet of any building or the position of any

building proposed to be built. Cellulose materials are attractive food

sources for subterranean termites that can then move into the structure.

- Prior to concrete placement,

remove all cellulose-containing material such as form boards from the area

encompassed by the foundation and the area within one foot of its

perimeter. The fill material should be free of vegetation and foreign

material.

- Prior to concrete placement,

clean all cellulose-containing material from cells and cavities in masonry

units, and from air gaps between brick, stone, or masonry veneers and the

structure.

- After all foundation work is

completed, remove all loose wood and debris from the crawl space and

within one foot of the perimeter of the building. All wood forms and

supports should be completely removed.

- Eliminate sources of chronic

moisture in and around the structure. This is one of the most important

requirements for successfully managing subterranean termites, carpenter

ants, and wood boring beetles. Good drainage design will help to prevent

moisture build-up in and around the building or structure.

- Use moisture barriers. In

above-ground foundations, moisture barrier films such as 6 mil

polyethylene can be used to cover the area under the structure. This will

help decrease moisture buildup in sub-flooring. Some builders recommend

the use of moisture barriers under slab foundations as well.

- Slope all exterior grades away

from the structure to provide drainage.

- Construct and seal all

adjoining components such as porches and planter boxes to prevent moisture

and soil contact with the structure.

- Design exterior landscaping so

it does not cause moisture build-up around the foundation. Maintain

clearance between vegetation and exterior walls.

- Align and/ or shield sprinkler

irrigation heads to direct spray away from the building.

- Place foundation wall vents to

provide cross ventilation for buildings with crawl spaces. If regrading or

remodeling covers vents, additional vents may be needed.

- Provide adequate clearance to

allow access for inspection and control if needed. Construct decks,

fences, patios, planters, or other wooden structural components that

directly abut the sidewall of the foundation or structure to provide: (a)

an 18-inch clearance beneath or, (b) provide for 6-inch clearance between

the top of the component and the exterior wall covering or, (c) have

components that are easily removable by screws or hinges to allow access

for inspection of the foundation sidewall and treatment for termites.

- Eliminate gaps around floor

joists. Floor joists should be built in or fitted onto joist hangers.

- Build floors to be durable,

non-absorbent, anti-slip, without crevices, and capable of being

effectively cleaned. If concrete is used, it must be steel-float finished

and sealed. Slope floors sufficiently for liquids to drain to trapped

gullies or drainpipes. The floor area under food preparation equipment

should allow easy cleaning of food spills and remain open to prevent

harborage.

- In areas where hazard from

termite damage is most critical, use floor framing of natural and durable

wood and follow the proper methods of termite protection for foundations.

- Provide adequate ventilation.

Allow at least 18 inches of clearance under floor framing and at least 12

inches under floor girders. Proper ventilation and use of vapor barriers

on the ground in the crawl space will help prevent the moist conditions

that subterranean and dampwood termites favor. The minimum ventilation

requirements in building or

structure must be based on the ratio of the net free vent area (a

measurement of a vent’s unrestricted opening) to the area of crawl space

to be ventilated.

Exclusion

- Install wall cavity closures

and avoid joist/ rafter gaps. Cavity closers should be installed at the

top of all cavity walls and there should be no gaps between joists and

rafters. This will keep out various pests that have gained access to the

attic such as birds, mice rats and squirrels.

- Eliminate gaps around wall

penetrations. Wherever drains, hoists, and vents, conveyors, pipes, cable

conduits or ducts pass between buildings through walls or foundations,

they should be sealed to prevent the spread of any infestation from one

building to another.

- Equip storage areas with

self-closing doors to deny pest access.

- Eliminate cracks and crevices,

that is, with sealant, or copper or bronze wool wherever possible,

especially in kitchens and other food preparation and storage areas.

- Eliminate dead spaces inside

storage areas to restrict areas where rodents may hide. Dead spaces

include double walls, false ceilings, enclosed staircases, boxed plumbing,

and voids or false bottoms under cabinets.

- Do not use wall coverings that

provide insect harborage. Do not install pegboard in kitchens, or other

food service areas, animal rooms, or laboratories.

- Construct walls for easy

cleaning. Wall surfaces are best when smooth, impervious, non-flaking and

light-colored, and must be capable of being thoroughly cleaned. Do not use

absorbent emulsion paints. Stainless steel splash-backs are recommended

behind sinks and working surfaces. Coving should be used at wall to floor

and wall to ceiling junctions to help cleaning operations and minimize

debris accumulating. Avoid construction of wall-to-wall junctures less

than 90 degrees. Slope floors in kitchen areas to provide good drainage

after cleaning.

- Use durable, non-absorptive

shelving material. Keep shelving far enough away from walls to leave room

for cleaning.

- Areas where susceptible items

are stored should be well lighted for ease in cleaning and inspection.

Moisture

management

- Ventilate cavity walls.

Adequate ventilation must be provided but any openings into the roof for

this purpose must be screened with mesh or hardware cloth.

- Eliminate gaps around joists.

On multi-story buildings or structures, floor joists should be built in or

fitted onto joist hangers.

- Seal all internal partitioning

wall and ceiling cavities.

- Build for ease of maintenance.

Suspended ceilings should be made of metal lattice incorporating cleanable

panels. Aluminum backed and faced fiberboard has proved successful in many

food factories. Flush-fitting ventilation grilles should be installed

tightly enough to eliminate openings around the edge of the grille. Solid

ceilings should be well insulated to avoid condensation and mold growth,

and should be smooth, fire-resistant, light colored, coved at wall joints,

and easy to clean.

- Build in inspection and maintenance access. Suspended

ceilings are helpful in hiding horizontal pipe work and services but

access for inspection for pests and maintenance must be built in.

Structural walkways should always be provided in large premises.

- Seal utility entry points on

the building exterior. Junctures where utilities such as pipes and cables

enter structures require special consideration to prevent pest entry.

Pests, especially rodents, often find easy access into buildings through

holes beside water pipes and electrical conduit, and through the cold air

return ducts on forced air furnaces. Utility entry points include exhaust

vents and underground electrical lines. Power lines have always been a

favorite route of travel for rodents, especially rats. Old, unused

openings where utilities formerly entered the structure should also be

inspected for cracks, broken screens, damaged doors, and uneven floors

near doorways. Any external meter boxes must have close-fitting doors; all

connected pipes or wires must be adequately sealed.

- Seal entry points within the

structure. Once inside the wall, pests may gain entry into the main

structure along electrical lines, pipes, poorly sealed fire wall

sheathing, or around furnace ducts, hot water heaters, or laundry drains.

If pests are able to reach the attic, they may travel from room to room or

unit to unit through openings for pipes, ducts, and wiring.

[Pipes, ducts or cables passing through walls should fit

tightly or be built into fire stops. Protect joists with metal flanges where

pipes or ducts pass through floors and walls. Hot water pipes should be carried

in sleeves through vertical or horizontal partitions. Surround the base of

elevators, conveyors and machinery with a 2-foot high smooth metal fence;

conveyor ends should have tight-fitting doors. Seal around all electrical

conduits, plumbing, heating pipes, trunking or service ducts that pass through

them.]

- Seal duct work. Ensure that all

heating and air conditioning ducts are tightly sealed at seams and joints.

- Ensure that all pipe insulation

has a smooth surface and that there are no gaps between pieces.

- When installing pipes, cables

and fittings, build in or allow enough wall clearance to enable cleaning

around the entry point. Flexible fittings are recommended for gas

fittings. All electrical switches should be flush-fitted.

- Ensure that doors are properly

installed and correct problems that interfere with a close fit. Pest entry

problems can arise when doors are hung unevenly or too high, or lined with

unprotected soft rubber weather stripping. Insects and rodents, especially

mice, often find easy access to buildings through open doors or under and

beside poor-fitting doors, particularly in receiving areas and garage

areas.

- Ensure that roll-up or overhead

doors are well fitted. With the door closed, check for gaps along the

sides, bottom, and top of the door. A gap at the top is common. Roll-up or

overhead doors often provide easy entry for rodents, birds, and bats. Rats

and mice can easily climb up the space between the door and the inner wall

or track to the top, where they gain entry and climb down the inside of

the track. Gaps between the track and the wall are also common, especially

if the track has been installed on brick walls. Door bottoms may be bent

or damaged, leaving gaps along the floor. Uneven floors due to frost

heaves may leave gaps when the door is closed.

- Use self-closing doors. All

doors should close on a level threshold, have smooth, non-absorbent

surfaces, be tight fitted and self-closing. Doors of bin rooms below

refuse chutes should be self-closing, flush-fitted and of metal

construction.

- Select door styles for ease of

maintenance and durability. Use polypropylene or toughened rubber doors

for ease of maintenance.

- Correct mail slot/ letter

plates that are not at least 30 inches above ground level to prevent them

becoming 'rat flaps.'

- Avoid the use of door frames

with acute angles.

- Use woodwork that is

well-seasoned, properly-knotted, stopped, primed, and given three coats of

polyurethane paint.

- Modify conventional doors. External

doors should be fitted with metal kick-plates not less than 1 foot high

and the metal plates should also fit jambs and door linings.

- Use nylon bristle door sweeps;

these are remarkably versatile for pest-resisting conventional doors.

- Install close-fitting windows

and screens. Poorly fitted windows or screens allow easy rodent entry from

exterior utility lines and pipes running along exterior walls. Runways

going to window ledges are often observed on stucco and brick walls and in

ornamental plantings next to buildings. Screens on windows, crawl spaces,

and vents are often damaged in government buildings and structures. Check

these carefully for needed repair or replacement.

- Slope window ledges. Window

ledges or other essential projections should slope at 45 degrees to

discourage birds from perching and roosting on them.

- Modify windows to prevent

harborage and access for pests, with no clear passageways to inside.

Modify weep holes, that is, openings that allow drainage of moisture in

window frames, that is, with copper or bronze wool to prevent access by

paper wasps and other insects.

- Do not install exterior features that attract insects,

rodents, birds or other wildlife. Avoid installation, particularly near

entrances, of the following:

o Light fixture designs that may provide opportunities for

bird perching, roosting or nesting;

o Decorative lattices or other structural features that may

inadvertently serve as bird roosts, over entrances to food services facilities;

and

o Structural features that provide opportunities for rodent

harborage or burrowing. Install bird-proof barriers (e.g., netting) that are

designed to prevent both pigeon and sparrow access to preferred nesting sites.

- Use enclosed fire escapes to

eliminate bird perching, roosting and nesting, and access for other pests.

- Use durable pest-proof

construction materials. Buildings and structures are constructed from

types of materials and design methods that vary greatly in the degree of

susceptibility to pest infestation, for example, metal and concrete versus

wood. Most structures eventually become less pest-proof due to

deterioration, alteration, or lack of repair. Pre-fabricated building

panels usually provide more opportunity for infestation to develop than do

solid brick or concrete walls; certain partition or cladding materials

such as chipboard, hardboard or block board offer little resistance to

gnawing of rodents and may, especially if damp, encourage molds, booklice

and fungus beetles.

- Avoid rough finishes that can

be gnawed or provide foothold. Rats and mice will climb up rough exterior

surfaces so it is best to eliminate such finishes and to avoid projections

or ledges which might give a foothold or provide access to any higher

points of entry that are unlikely to be as well proofed as those on the

ground floor.

- Screen or otherwise eliminate

animal access under decks, porches, and stairways. Seal porches and ramps

to the building foundation with hardware cloth screen mesh to form a

barrier to digging pests such as rats and skunks. This screen must extend

12 inches into the ground and must have a right-angled, 6-inch wide,

outward extending shelf to prevent burrowing under the screen.

- Use gravel to discourage

burrowing. Where feasible and inaccessible to people, maintain a 2-foot

pea gravel strip around buildings to prevent rodent burrowing.

- Install guards on pipes and

downspouts. Standard conical or rectangular metal rat guards should be

fitted to soil pipes and rainwater downspouts, projecting about 9 inches

from the pipes and built into the walls at the point where they touch it.

Fit tops of open pipes with balloon guards. Mesh fitted over rainwater

downspouts will keep out nest debris.

- Design exteriors that have no

access to wall cavities. To protect against mice, no external or other

cavity wall should have any holes larger than ½ inch in diameter. Modify

weep holes, that is, with screening in walls to prevent access by insect

pests.

- Install fitted grills over air

intakes.

- Consider pest management when landscaping near buildings

and structures.

I. EXTERIOR SIDING

- Avoid gaps at edges and

corners. Wood or masonite siding is especially vulnerable to warping and

cracking near corners and around the base of the building and structure.

Buildings constructed with ribbed or corrugated metal siding allow rodent

entry if the bottoms of the siding panels do not rest flat on a solid

surface or they are not otherwise closed off. Sections of pre-fabricated

buildings or structures should be assembled tightly, and gaps at joints

should be covered with metal flashing; joint gaps are often left open,

especially at corners and at the foundation/ slab interface.

- Allow clearance for inspection

between siding and soil surface in order to provide access to inspect for

termite infestation, and to prohibit exterior siding contact with soil,

clearance between exterior wall coverings, that is, stucco, siding, and

soil on the exterior of a building should not be less than 6 inches.

- Irrigation/ sprinkler systems

and risers for spray heads should have sprinkler heads or be located two

feet from the building and structure so as to prevent water contacting

walls; including drought tolerant plants in landscape plans can aid in

achieving this goal.

- Eliminate rodent access under

shingles. Shake shingle roofs allow rodent entry if the roof is not

solidly sheeted with plywood or similar material and the shingles are not

properly fitted. Use vents with tightly fitted double roof jacks and/or

heavy-duty screen to prevent small animal access.

- Build tight roof joints and

protect with flashing. Ensure tightness of all roof joints and the

presence of flashing if rats and mice have access to the roof via wire,

pipes, plants, or rough-textured walls. Ensure proper installation of

metal flashing on roof, wall joints and edges.

- Fit eave roof tiles with bird

stops. This will also exclude bats, bees and wasps.

- Make sure all attic and soffit

vents are properly screened to exclude insects, birds, and other animals.

Use hardware cloth screen mesh.

- Direct water from drainage and

sprinklers away from walls. All condensate lines, and roof down spouts

should discharge at least one foot away from the structure sidewall,

whether by underground piping, tail extensions, or splash blocks. Use

gutters with down spouts on all buildings with eaves of less than six

inches horizontal projection except for gable end rakes or on a roof above

another roof.

- Locate site away from building and

structure entrances or at least 50 feet from doorways.

- Design site with properly

graded concrete or asphalt pads to help prevent rats from establishing

burrows beneath them.

- Build to exclude vertebrates.

Build refuse sites with a solid enclosure that extends all the way to the

ground. Use metal or synthetic materials, as opposed to chain-link or

wood, to prevent rodents and other wildlife from gnawing or climbing the

enclosure.

- Close off refuse, recycling,

and trash storage areas. If trash will be stored, design storage areas

that can be closed off from the rest of the building. Locate storage areas

for boxes, paper supplies, and other materials in areas separate from

where food or trash is stored. When stored together, these materials put

food and shelter together, favoring pests.

- Place outdoor garbage

containers, dumpsters, and compactors on hard, cleanable surfaces.

- Include a water source at the

site for cleaning permanent storage containers and pad surfaces; ensure

adequate drainage.

- Floor cavities should be sealed

where they enter shafts or chutes.

- Shafts or chutes should be of

smooth internal construction. To the extent feasible, build or modify

these areas, that is, use coving at floor to wall junctures, or other

means of minimizing corners and sharp angles to reduce debris accumulation

and to facilitate cleaning.

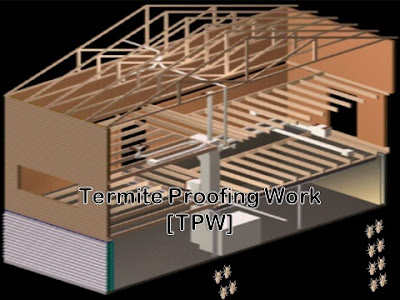

2. PRE-CONSTRUCTION

TERMITE PREVENTION GUIDELINES AND BEST PRACTICES

SCOPE OF WORK:

· All labor, materials, and equipment to render the soil treatment, treatment of all wooden structures, among others shall

be furnished by the

National Committee on Urban Pest Control

Licensed Pest Control Provider; and

· The

National Committee on Urban Pest Control

Licensed Pest Control Provider shall treat

the soil under the foundation footings, walls, floorslabs, and perimeter to

make them impervious and toxic to subterranean termites and shall make the soil

of termite environment uninhabitable for a long period of time.

CHEMICALS

TO BE USED:

·

The

National Committee on Urban Pest Control

Licensed Pest Control Provider shall use

only approved

NCUPC Registered environment-friendly termiticides with no health risks and proven effective against the target pests.

·

The

National Committee on Urban Pest Control

Licensed Pest Control Provider shall render

the complete Termite Proofing Work (TPW) program in the following manner during

the construction of the building and structure:

TREATMENT

PROCEDURES TO BE FOLLOWED:

This pre-construction treatment to termite

proofed government building and structure shall follow the three phases of

building and structure as follows:

PHASE I - SOIL TREATMENT

·

Thorough treatment by spraying of the soil of

the foundation footings, walls or sidings, floorslabs

and along the outside perimeter of the building after these had been fully

leveled off and ready for cementing;

·

Demolition of the termite mounds in the

surroundings (if any)

of the government building and structure. Termite mounds are

homes of subterranean termites, and they are sources of structural termite

damages.

PHASE II - TREATMENT OF BUILDING WOODEN

SKELETAL FRAMEWORK

·

Thorough treatment of the rough hollow blocks, walling, floor beams, joints, girders, frames, windows,

doors, and other parts of the household, structure and facility.

·

Thorough treatment of the skeletal ceilings,

frames, girdles, and other parts of the household, structure and facility.

PHASE III - FINAL TREATMENT

·

NCUPC Registered Environment-friendly

termiticide, in powder form, with no health

risks

shall be properly applied by wood injection or

through trophallaxis method in all places liable or possible termite

infestation and termite passages such as electrical conduits, double walling,

panel baseboards, cabinets, ceilings, roofing beams, cement cracks, etc.

·

This is done after the completion of the

building or just before the occupancy of the building.

3. EXISTING

GOVERNMENT BUILDING AND STRUCTURES TERMITE AND PEST PREVENTION AND CONTROL GUIDELINES

AND BEST PRACTICES

For effective prevention and/ or control of

termites in government buildings and structures, the National Committee on Urban Pest Control Licensed Pest Control Provider

hereby recommend the following technical services following a process of

treatment procedure described as follows:

TECHNICAL SERVICES:

A. SOIL TREATMENT (ST)

·

ST prevents subterranean termites from

damaging the wood component of the building and structure by properly treating

the soil around it using appropriate equipment by either cordoning, trenching

or injection method. The distance shall

be about l8-20 inches apart and about six inches close to the external wall of

the building and structure.

·

ST uses only

approved

NCUPC Registered Environment-friendly termiticides

with no health

risks and proven effective

against the target pests. This creates soil that is an

uninhabitable environment for subterranean termites.

·

This

is accomplished by using a power machine operated and run by a five-horse power

(5HP) machine at a pressure of 150 Psi and at an approximate rate of 2 gals.

solution per 45 seconds. Dilution rate

of the termite should be strictly followed and complied with by the National Committee on Urban Pest Control

Licensed Pest Control Provider.

·

Treatment Frequency: One General Treatment (GT) Only.

B. DRILLING SERVICE

·

Drilling

service is done in order to treat the soil under cemented floorslabs using heavy-duty HILTI FE24 Rotary Hammer

Drill (220V/ 740W) with the speed under load of 275-570 rpm and hammering power

of 3,100 blows/ minute and drilling performance in medium-grade concentrate of

40 cubic meter per minute = 260 mm/ min. Recommended diameter range is 12-20 mm

diameter, using heavy-duty Black & Decker bit of 48 cm long in diameter.

· Before

any drilling service is conducted in building and structure, the building

management should provide the National

Committee on Urban Pest Control Licensed Pest Control Provider with a floor

plan indicating underground water, electrical and puso negro pipes.

· Perimeter

drilling distance is one (1) meter apart and six (6) inches close to the wall.

· With

this service, we can inject only approved NCUPC Registered Environment-friendly termiticides solution with

no health risks and proven effective against the target pests through soil

injector using the power machine deep under the surface to penetrate the hidden

areas so susceptible to subterranean termites with a rate of two (2) gal.

solution per hole. This gives greater structural protection.

·

Treatment Frequency: One (1) Treatment Only.

C. WOOD DRENCHING (WD)

·

WD is designed to treat all infested parts of the building and structure, concentrating on the floors, walls, baseboards, cracks and crevices by direct spraying of only approved NCUPC Registered Environment-friendly termiticides with no health risks and proven effective against the target pests at a correct dilution rate.

WD is designed to treat all infested parts of the building and structure, concentrating on the floors, walls, baseboards, cracks and crevices by direct spraying of only approved NCUPC Registered Environment-friendly termiticides with no health risks and proven effective against the target pests at a correct dilution rate.

· This

treatment is to control the surface infestation on the spot and help minimize

further infestation in the building and structure.

·

Treatment

Frequency: One General Treatment (GT)

Only.

D. TERMITE ABATEMENT MAINTENANCE PROGRAM (TAMP)

·

TAMP service is properly accomplished and done by dusting or trophallaxis method. Treatment of the infestation by injecting only approved NCUPC Registered Environment-friendly termiticide powder with no health risks and proven effective against the target pests at a correct dilution rate in the doorjambs, electrical outlets, panel boards, double walling, and cabinet. Either a rubber or plastic applicator may be used in order to treat the infested areas and other possible susceptible areas for termite.

TAMP service is properly accomplished and done by dusting or trophallaxis method. Treatment of the infestation by injecting only approved NCUPC Registered Environment-friendly termiticide powder with no health risks and proven effective against the target pests at a correct dilution rate in the doorjambs, electrical outlets, panel boards, double walling, and cabinet. Either a rubber or plastic applicator may be used in order to treat the infested areas and other possible susceptible areas for termite.

· If

the building and structure is already termite infested, there’s nothing like a

regular termite check-up. During the General Treatment (GT) and Quarterly Treatments

(QT). Only National Committee on Urban

Pest Control Certified Applicator shall conduct the inspection and

treatment to minimize the possibility of an infestation by drywood termites,

dampwood termites as well as subterranean termites.

·

Frequency: One General Treatment (GT) Only, and

Quarterly Treatment (QT) per quarter for a

period of One Year.

E. BUKBOK

ABATEMENT MAINTENANCE PROGRAM (BAMP)

· Wood-boring

beetle or “bukbok” make pinholes on the walls causing sawdust on your floors

and eventually damage the building and structure. Although not as numerous as

the termites, this pest is much harder to control.

· Depending

on the severity of infestation, BAMP may be done in the following manner: Spray or brush the infested area thoroughly,

inject every pinhole with a termiticide concentrate or conduct fumigation to

wipe out the infestation.

·

Treatment

Frequency: One General Treatment (GT)

Only.

F. MOUND

DEMOLITION (MD)

· Termite

mounds are the homes of subterranean termites. These colonies are where the

queen lays eggs and the king, secondary reproductive, soldiers and workers

live. Termites attack and penetrate the

building and structure even if these mounds are 200-500 feet away from the building

and structure.

·

Only

National Committee on Urban Pest Control

Certified Applicator shall search for these termite mounds in the

surroundings, demolish them, retrieve the queen, and thoroughly treat the

surroundings using only approved NCUPC

Registered Environment-friendly termiticide with no health risks and proven effective against the target pests.

Treatment

Frequency: One General Treatment Only.

No comments:

Post a Comment